Define Undercut In Welding

It also can be caused by too high amperage. One reason for this defect is excessive current causing the edges of the joint to melt and drain into the weld.

Welding Defects Step By Step Causes And Preventions Weld World

Welding Defects Step By Step Causes And Preventions Weld World

When it comes to one of the severe welding defects then undercutting takes the prominent place.

Define undercut in welding. To cut away material from so as to leave a portion overhanging as in carving or sculpture. Undercut or undercutting in welding is the term given to a groove that develops at the base or root of the metal. This leaves a drain-like impression along the length of the weld.

An undercut is a kind of weld defect which forms a groove in the parent metal along with the sides of the weld bead. A high current results in a higher and narrower weld with a greater penetration depth. Weak welds can damage equipment or materials injure or even kill.

Verb used without object undercut undercutting. It is a widespread problem and even the most experienced welders sometimes face this issue. This defect usually occurs when you try to make weld with either fast travel speed or high welding current.

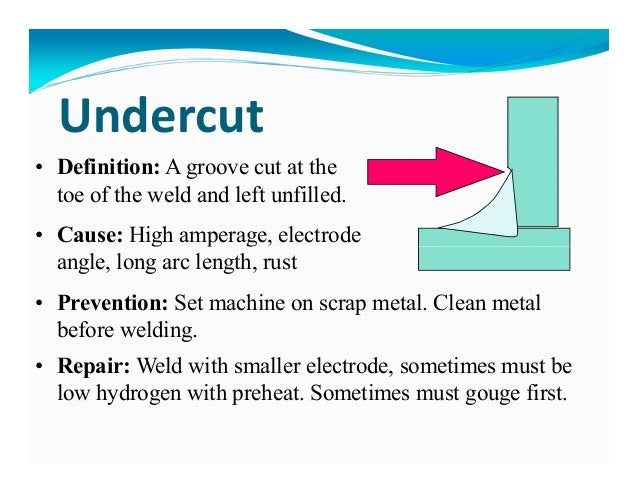

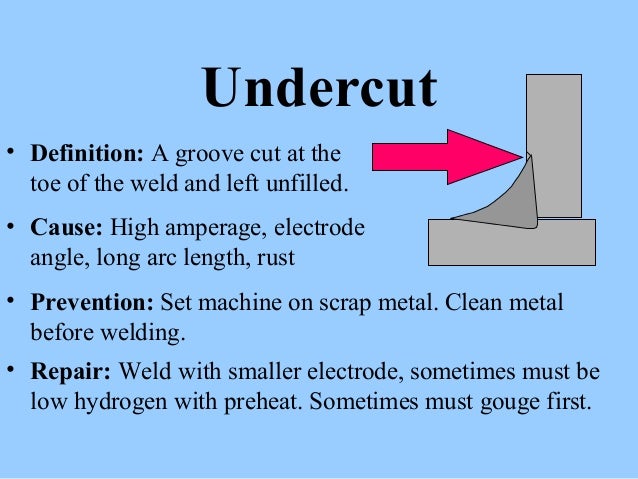

A groove in simpler terms is a long and narrow cut in hard material. The first is the melting away of the base material at the side wall of a groove weld at the edge of a bead which produces a sharp recess in the side wall in the area where the next bead is to be deposited. Undercutting in welding is a weld defect usually characterized by a groove formation at the weld toe this occurs when the free edges of the weld metal or base metal are overheated.

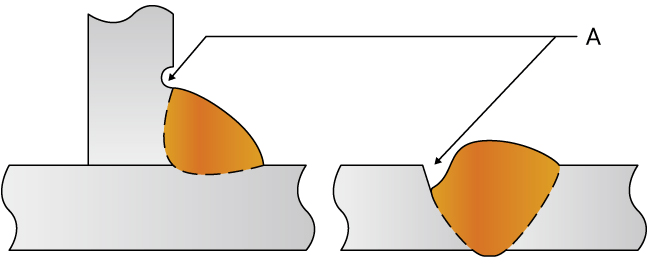

A weld discontinuity in which fusion did not occur between the weld metal and the fusion faces or the adjoining weld bead Define Incomplete Joint Penetration. In welding undercutting is when the weld reduces the cross-sectional thickness of the base metal. Undercutting happens when the weld metal fails to fill in that grooved area.

Undercut is defined as a groove melted into the base metal adjacent the weld toe or weld root and left unfilled by weld metal. Then the weld bead will be very peaked because of its extremely fast solidification. An undercut is a flaw or imperfection that is characterized by a hollow formation on the weld toe due to overheating at the edges of the base metal.

This is a weakness in the weld that typically is caused by when the travel speed is too high. Undercutting is when the edge of a weld has an inverse U shape. Undercutting is when the weld reduces the cross-sectional thickness of the base metal and which reduces the strength of the weld and workpieces.

Weld Defect - UNDERCUT POROSITY SLAG INCLUSION and UNDERFILL are all defects which can adversely affect a weld usually causing a crack which weakens it. To offer goods or services at a lower price or rate than a competing price or rate or than that of a competitor. To undercut material a competitor a ball etc.

The weld current affects penetration and deposition rate. It is an abnormality that can be summed up as an unfilled groove that exists along weld edges. Groove reduces the thickness of the plate and also reduces the strength of the weld.

This type of defect reduces the strength of the weld and workpieces. When the base of metal melts away from the weld zone then a groove is formed in the shape of a notch then this type of defect is known as Undercut. Not enough filler metal welded into groove making the total thickness of the weld less than the total thickness of the base material next to the weld.

Examples and translations in context Selfcutting undercut anchor according to Claim 6 characterised in that the hardened protrusions 10 are welding points andor welded on spring steel elements. Too high a welding current can result in undercuts an uneven weld convexity burn-through thermal cracking an inappropriate merging angle with the body material and undercutting. Undercutting is common and costly.

Undercut welding definition in the English Cobuild dictionary for learners undercut welding meaning explained see also undercurrentundercoatunderundertow English vocabulary. Previous Post Undercut Gauge Next Post Velocity. Undercutting is a groove that develops in the base metal near the toe or root of the weld.

The term undercut describes two specific conditions. This results in a feeble weld that is likely to have some cracks along the toes of the weld. It reduces the fatigue strength of the joint.

The major cause of undercuts in welding is when the operator welder uses a high welding current or welds with fast travel speed. One reason for this type of defect is excessive current causing the edges of the joint to melt and drain into the weld. This leaves a drain-like impression along the length of the weld.

What Causes Undercut In Welding And Possible Remedies Arc Helmets

What Causes Undercut In Welding And Possible Remedies Arc Helmets

Welding Defects Types Causes And Remedies Engineering Blog

Welding Defects Classification Causes And Remedies Welding Ndt

Welding Defects Classification Causes And Remedies Welding Ndt

Welding Defects And Discontinuities Ppt Video Online Download

Welding Defects And Discontinuities Ppt Video Online Download

Welding Defects Total Materia Article

Welding Defects Total Materia Article

What Is Undercut In Welding And How To Avoit It Weldingmania

What Is Undercut In Welding And How To Avoit It Weldingmania

Radiograph Interpretation Welds

Radiograph Interpretation Welds

What Is Undercutting In Welding Welding And Inspection Welding Inspection Community

What Is Undercutting In Welding Welding And Inspection Welding Inspection Community

What Is Undercutting In Welding Causes And Prevention

What Is Undercutting In Welding Causes And Prevention

Surface Defects That Impair Welding Quality Welding Quality And Problems Automated Welding Basics Keyence America

Surface Defects That Impair Welding Quality Welding Quality And Problems Automated Welding Basics Keyence America

Types Of Welding Defects And Remedies

Types Of Welding Defects And Remedies

Welding Defects Porosity Arc Strikes Undercut Youtube

Welding Defects Porosity Arc Strikes Undercut Youtube

Pittsburgh Cwi Seminar Nightmare Undercut Vs Underfill

Pittsburgh Cwi Seminar Nightmare Undercut Vs Underfill

Different Types Of Welding Defects And Remedies Student Lesson

Different Types Of Welding Defects And Remedies Student Lesson

The Most Common Welding Defects Causes And Remedies Technoweld

The Most Common Welding Defects Causes And Remedies Technoweld